Customer Cases

Understanding how customers from various industries achieve digital transformation through HEADING technology

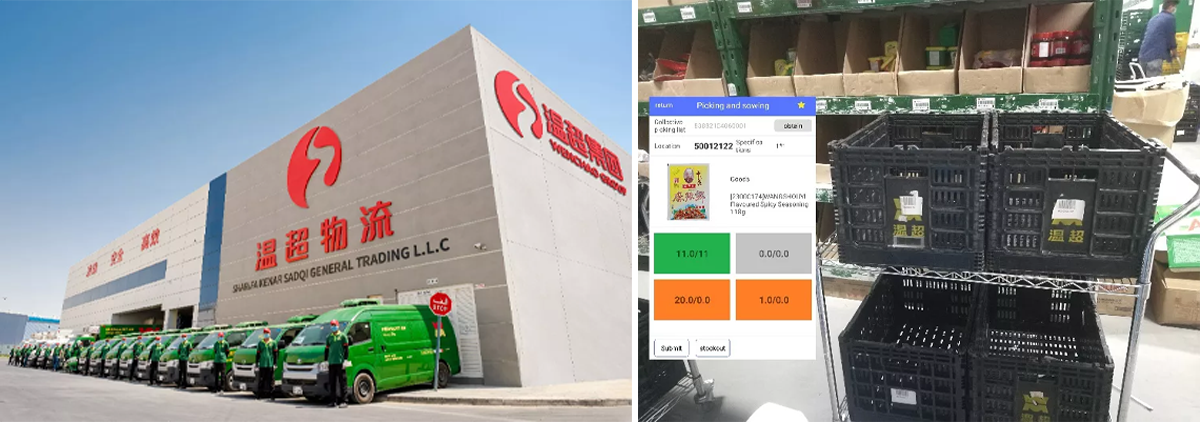

WENCHAO

WenChao Group was founded in 2006, headquartered in the International City area of Dubai, a hub for the Chinese community. It is a conglomerate integrating eight major industries: retail supermarkets, farms, e-commerce, logistics, tea culture, trade, fully intelligent central warehouses, and global procurement. In Dubai, it owns an 8000 square meter self-built distribution center.

HEADING Solution

After coordination and preparation between Wen Chao and HEADING, the team completed the launch of the Wen Chao Distribution Center HDWMS system in March 2021. This system supports Wen Chao's multi-temperature layers for ambient, fresh, and frozen products, as well as multi-format business operations in supermarkets and e-commerce. It also provides a bilingual system for foreign employees.

Project Highlights

-

Multi-position inventory level management

1. Multi-format management Set up multiple positions to support different inventory management and shipping methods for supermarkets and e-commerce;

2. Unidirectional inventory sharing Share the main warehouse inventory unidirectionally to the e-commerce warehouse, reducing the out-of-stock rate for e-commerce and avoiding situations where there is inventory but no stock;

3. Automatic cross-warehouse replenishment Unidirectional inventory sharing can generate cross-warehouse replenishment orders automatically based on upper and lower limits, eliminating the need for manual requisition and reducing intermediate processes and personnel operations;

4. Selective refinement management Concentrate temperature layer management, processing, and other operations in the main warehouse, reducing the management difficulty of the e-commerce warehouse and improving the clarity of inventory management in the e-commerce warehouse; -

Fresh food processing is directive and procedural

1. The system automatically generates processing tasks based on the historical shipment data of finished products and the current inventory of raw materials in the warehouse. Employees only need to obtain processing instructions on handheld terminals to proceed with processing. This reduces human intervention, improves operational efficiency, and enhances the accuracy of processing volumes.

2. The processing uses a combination of electronic scales and system integration to strictly manage the process and control processing losses. -

E-commerce business management

1. A separate picking area reduces the space size of single-item picking positions, decreases the overall area of the picking zone, and shortens the walking distance for pickers.

2. Adopting a combination of batch picking and individual order picking modes. Batch picking: Splitting numerous picking orders into several batches, each batch including multiple picking orders. During picking, the pick-and-pass mode is used for a specific batch, allowing multiple picking orders to be completed simultaneously, reducing the redundant and ineffective walking distance of the picking staff. Individual order picking: The system automatically identifies picking orders with larger demand volumes. For such orders, no batch processing is done; they are picked individu- ally to prevent large orders from affecting the completion time of other orders and to balance the carrying capacity of the picking tools.

-982.jpg)